In this edition:

DOWNLOAD THE PDF NEWSLETTER

Feature article

See How TMG Is Breaking Ground on Industry 4.0

Since the 18th century, there have been three major industrial revolutions: the introduction of steam power and mechanization, the addition of electricity and mass production, and the rise of automation in factories with computers, shaping modern practices.

However, it’s agreed by many that we’re currently amidst the middle of a fourth industrial revolution (Industry 4.0), and companies like TMG are shaping what the future of production will look like. The emerging trend? ‘Smart Factories’ utilizing Artificial Intelligence (AI), digital twinning simulation, Augmented Reality (AR), and comprehensive analytics and reporting tools to create an ecosystem that efficiently works together.

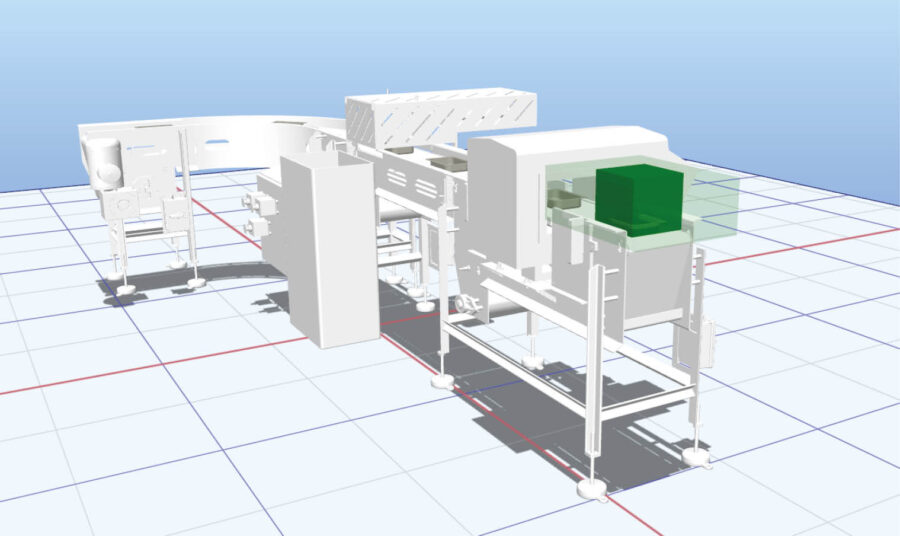

TMG is placing itself at the forefront of this revolution by investing in concepts like digital twinning. This innovative process of creating a ‘digital twin’ of complex systems allows for clients to mirror exactly how a system will interact with real product. These simulations provide unprecedented levels of quality assurance throughout the design process, providing realistic impacts of product weights and dimensions as they run through the system.

After fabrication, TMG is developing new and innovative ways to incorporate remote monitoring via Human Machine Interface (HMI) dashboards. These dashboards essentially turn every machine in a facility into a ‘smart machine’ by consolidating data such as maintenance logs, failure history, temperature, and vibration into a single, easily accessible interactive display.

If combined with AI powered predictive maintenance algorithms, entire plants can use these simulations and smart machines to forecast maintenance needs. This proactive approach provides a completely autonomous way to boost efficiency, reduce downtime, and lower operational costs by always staying up to date.

And when it’s time to get boots on the ground to perform this maintenance,

solutions like TMG’s specialized Augmented Reality (AR) goggles can be utilized to connect with subject matter experts from any location. These goggles allow a technician on the floor to share exactly what they’re seeing, and have the connected party interact with parts in real time.

“TMG’s work surrounding Industry 4.0 is the key to unlocking new levels of Overall Equipment Effectiveness (OEE)” shared Krystal Darling, CEO of Tri-Mach Group.

By equipping every machine with the ability to autonomously monitor, analyze, and present data surrounding its day-to-day function, modern day smart factories can achieve levels of effectiveness only imaginable in previous decades. Reach out to our team of experts today to hear more about Industry 4.0 at TMG.

SKILLED TRADES EXCELLENCE

TMG Shapes the Next Generation of Tradespeople

Last year the Canadian Government estimated the retiring of over 700,000 skilled trades workers, and urged that the number of new entries will not be able to keep up with demand.¹ TMG recognizes this shortage and is committed to providing access to new opportunities for young Canadians with different programs and educational events tailored to introducing students to diverse trades careers, including millwrighting, electrical, fabrication, piping, painting, automation and engineering.

TMG ‘Tricks of the Trades Days’ allow participants to spend immersive days shadowing various departments. By giving members of our community the chance to see first hand what a day in the life looks like for one of Canada’s finest tradespeople.

One standout event was a recent welding demonstration. This event, designed for high school students enrolled in trades-related courses, gave students the opportunity to learn with their hands; getting to experience a day in the life of a welder. Students shadowed stations and even put their newly found skills to the test and welded their very own piggy banks to take home, a symbol to this investment into their future.

On top of student focused events, TMG also hosts guidance counselor days aimed at equipping Ontario High School Teachers and guidance counselors with insights to share with students about future career opportunities in the trades. By working

with our local high schools, TMG hopes to give young Canadians exposure to obtaining a rewarding career in the trades. Want to be a part of a TMG event? Get in touch with our team today.

Skilled Trades Accelerator Program

In July 2024, TMG proudly announced the launch of its Skilled Trades Accelerator Program. Taking place in the TMG Centre of Excellence, this program is a brand new initiative offering aspiring tradespeople a comprehensive training program and a clear pathway to becoming a skilled journeyperson, fostering a new generation of tradespeople.

The program begins with skilled trades bootcamp, where students begin with a 6-week classroom-based theory course, providing micro-exposure to critical components of various skilled trades, followed by a 6-week on-the-job rotation. Students who successfully complete bootcamp will then begin their Pre-Apprenticeship.

Over the next 9 months of on-the-job training, Pre-Apprentices will gain all the skills and knowledge in order to streamline becoming a Registered Apprentice within their chosen designation.

The Skilled Trades Accelerator Program is designed to provide a comprehensive, hands-on learning experience, ensuring that students will be successful in the trades career they wish to pursue.

Head to www.tri-machgroup.com/skilled-trades-accelerator-program to apply to be a TMG Pre-Apprentice.

CUSTOMER EXPERIENCE

Predictive Analytics | TMG INsite™

How the New Generation of Data is Changing the Way We Look at Manufacturing Strategy

Using historical statistics, monitoring sensors, machine learning algorithms, and data mining, predictive analytics offers an invaluable tool for analyzing data and making predictions about future events. By identifying patterns and trends in this data, predictive analytics is a major key to making informed business decisions.¹ In manufacturing, this is especially critical to three cornerstone functions: quality, efficiency, and cost reduction.

Recognizing the value of predictive analytics, TMG gathers equipment data through embedded HMI dashboards. Once we have data on each machine’s status, including maintenance logs, failure history, temperature, and vibration, we have the first step to kickoff predictive analysis. Through the below steps, TMG INsite™ is not only able to collect this data, but interpret it to offer personalized maintenance predictions to improve the cornerstones of manufacturing.

Key Components

The five main steps to predictive analytics include:

- Data Collection: Gathering historical and real-time data from various sources.

- Data Preparation: Cleaning and transforming data into a usable format.

- Modeling: Applying statistical and machine learning models to the data.

- Validation: Testing the models to ensure accuracy and reliability.

- Deployment: Integrating the predictive models into business processes.

Predictive analytics offers benefits for virtually every business open today – so let’s dig into the specific benefits to manufacturing:

Predictive Maintenance

Forecast equipment failures, enabling timely maintenance and reducing unplanned downtime. Early issue identification prevents costly emergency repairs and extends equipment lifespan, leading to significant cost savings.

Quality Control

Predictive models can analyze production data to detect patterns that lead to defects, enabling manufacturers to make proactive adjustments to their processes. This early detection and intervention not only enhances product quality but also reduces material waste.

Production & Supply Chain Efficiency

By forecasting demand more accurately, manufacturers can maintain optimal inventory levels, reducing carrying costs and minimizing stockouts or overstock situations. Analyzing supplier data helps identify reliable suppliers and potential risks.

Cost Reduction

All of the above efforts, if implemented correctly, contribute to a drastic reduction in overall cost by limiting downtime costs, emergency repair expenses, extending equipment lifespan, and optimizing inventory management.

1. What is Predictive Analytics? (IBM.com)

MANUFACTURING EXCELLENCE

How Tri-Mach Automated 6.4 Million Burger Patties

Earlier this year, Tri-Mach completed a transformative journey with a one of the world’s largest food producers based out of Missouri, USA. Their mission: revolutionize burger production for a global fast food giant without compromising quality or efficiency.

As a result of purchasing Tri-Mach Vertical Elevators and a new Smart Case Highway System, the existing client’s labor force dropped from 25-30 to a mere 4 employees, allowing the client to repurpose over 80% of the original workforce to less labor-intensive positions.

In the new process, burger patties emerge from freezers along a conveyor system, where instead of being greeted by a team of laborers, six uniquely engineered robots autonomously grab, stack, and pack the patties to the pre-programmed amount. An impressive 6.4 million patties now flow through this system daily.

An additional piece to this application was Tri-Mach’s Ever-Kleen® Vertical Elevators. By facilitating a new system for seamless product transfer from floor to ceiling, Tri-Mach was able to introduce a solution to expansion while maintaining spatial constraints for the client.

The use of Tri-Mach’s 3D scanner proved invaluable, ensuring precise design fit to a highly custom environment. Collaborating with Tri-Mach’s internal millwrighting team also provided deeper understanding of integration capabilities, and the success of this project introduced the creation of a dedicated systems department within the company.

After six full months with the new system in place, client feedback has been nothing but positive. Impressed by their new production capabilities, the client is now actively considering implementing this Smart Case Highway System across its global plants.

Industrial Contracting Solutions Takes on Major Custom Panel Project

A renowned global manufacturer of chocolate and cocoa products decided to take on a facility expansion project in early 2024. Their goal was to accommodate growing demand while maintaining operational efficiency. The project centered around fabricating 82 Remote I/O Cabinets, each crucial for seamless communication between field devices and the central control system.

Challenges: While the PLC Hardware was specified, other materials were open to alternative solutions. The goal was to find cost-effective options without compromising quality.

Solution & Result: ICS collaborated with trusted vendors to deliver Remote I/O Cabinets seamlessly integrated into the client’s facility, enabling real-time data exchange for efficient process control and monitoring while staying within budget. Additionally, thanks to ICS’ 40,000 sq ft facility and expert team, they were easily able to accommodate a project of this scale and turnaround the 82 panels in a tight timeline.

Advance Millwrights Automates Salt Bagging & Palletization

The cutting edge Certo-Tech bagging and palletization system just introduced a remarkable upgrade to a major salt and chemical distributor’s packaging process. The new system is designed to automatically sort and stack up to 20 bags per minute for two different product dimensions. Previously, the client had been relying on a manual bagger and traditional palletizer, which led to various efficiency issues.

The new solution utilizes fully customizable robotics to automate the entire process, ensuring precision and consistency in every bag wrapped and palletized. The flexibility of the Certo-Tech systems combined with leveraging ICS programming provided a swift and turnkey transition to automation. Interested in exploring how Certo-Tech Systems can automate your processes? Get in touch with our team at info@advancemillwrights.com.

INNOVATION & TECHNOLOGY

Smart Technology, Superior Performance | The Kleen-Lift® COLUMN PRO

Introducing the Kleen-Lift® Column Pro, offering best in class lifting speeds and capacity while maintaining a truly compact and portable footprint. Configurable to a variety of heights, the Kleen-Lift® Column Pro can also be set to autonomous operation for streamlined lifting.

Built for use with industry standard DIN 9797 400 lb. (200 liter), 600 lb. (300 liter), and a variety of custom dump buggies at 20 feet per minute, you can be confident that the Column Pro is built to spec for your application.

Consistent to Ever-Kleen® technology, the Column Pro’s head-to-toe 304 or 316 stainless steel build not only exceeds AMI guidelines, but also offers a completely open design to simplify washdowns and ongoing maintenance.

The integrated control panel with HIM display means that the Column Pro offers clear, concise readings of critical machine functions and controls. This also allows for greater connectivity for site-wide communication between other machines. “It’s a completely turnkey solution; there’s nothing else on the market as comprehensive as the Column Pro” said Maximillian Lundershausen, Product Development Supervisor at Tri-Mach.

“There’s no other dumper that offers as robust of features in this compact of a footprint. This is absolutely vital for when times are constantly increasing expectations to do more with less”.

Want to learn more about the Kleen-Lift® Column Pro? Click here.

IRONCORE™ Enclosed Conveyors

Enclosed conveyors are growing in popularity due to the following benefits:

- Contamination Prevention: Enclosed conveyors protect materials from external contaminants, ensuring product integrity during transportation.

- Weatherproof: These systems are waterproof, safeguarding against weather-related damage.

- Temperature Control: For temperature sensitive materials, enclosed conveyors can maintain specific temperatures.

- Enhanced Safety: Reduced finger pinch points and enhance workplace safety.

- Low Maintenance: Enclosed designs prevent belt buildup and residue, minimizing maintenance needs.

Advanced Millwrights takes our IRONCORE conveyors to the next level with intuitive heavy-duty enclosure options. Compatible with any IRONCORE conveyor, these enclosures are built for tough enviroments. Their low maintenance design improves product safety and promotes overall equipment effectiveness.

After 30+ years of designing solutions for bulk material handling within the agriculture industry, the IRONCORE series has become the standard for quality against tough environments. Their robust, fully enclosed, yet intuitive design minimizes dust emissions, ensuring a contaminant free environment while also allowing for access thanks to easy to remove enclosure design.

Any product build-up in a transfer system can lead to blocks, spills, or belt damage. All of which contribute to production delays, safety hazards, yield loss, and process inefficiencies. Top tier CEMA compliant idlers, blockage sensors, speed monitors, self cleaning wing pulleys, and electrically driven belt trippers ensure an efficient and blockage free flow of material.

Available in widths from 18-60”, mild, galvanized, or stainless steel, and a variety of capacities and motor options, the IRONCORE conveyor series offers custom solutions for any application.

Interested in learning more about what IRONCORE conveyors can offer your business for bulk material handling? Get in touch with our industry experts at sales@advancemillwright.com

PEOPLE & CULTURE

Putting Safety First at TMG

Furthering our commitment to a safety-first culture at TMG, the first half of 2024 has already been packed with safety training and development.

Company wide first aid training, safety vendor presentations, and the distribution of PPE bags were just a few notable mentions of the ongoing efforts from the TMG safety team. Consistent with TMG’s family oriented culture, the safety team engaged with the community by hosting a Kids Safety Drawing Contest and promoting health awareness through the Health and Wellness Fair. Finally, our safety talk during week four emphasized the importance of proper nutrition.

TMG keeps up with an ongoing commitment to employee safety by leading a monthly safety talk under the leadership of a dedicated Health & Safety Team.

At TMG, we view the investment into safety as a vital step towards providing exceptional service to our customers. With dedicated health and safety monitoring, TMG ensures safety is always top of mind at every site; ultimately reducing accidents, improving productivity, and upholding a standard of excellence across the board.

Pop Quiz

What kind of fire extinguisher is approved for electrical fires?

.

.

.

Answer: Class C

TMG Congratulates New VP of Operations Geoff Furlong

TMG is delighted to announce the promotion of Geoff Furlong to Vice President of Operations. With an impressive career spanning 15 years in engineering and people leadership, Geoff has consistently demonstrated exceptional expertise and commitment to manufacturing excellence.

TMG is delighted to announce the promotion of Geoff Furlong to Vice President of Operations. With an impressive career spanning 15 years in engineering and people leadership, Geoff has consistently demonstrated exceptional expertise and commitment to manufacturing excellence.

Geoff started his career at TMG as Sr. Director of Engineering in 2021, a role in which he has excelled. He quickly got to work streamlining processes, boosting productivity, and setting new efficiency standards. He built a strong engineering team across all three companies within TMG, all with a shared passion for innovation. His pursuit of an MBA reflects his commitment to continuous learning, enhancing his strategic decision-making. By revamping quality processes and introducing new technologies to streamline project management, Geoff has played a critical role in driving TMG’s growth and competitiveness within the market.

Geoff stated, “investing time and resources into our internal teams is at the foundation of everything we do. By empowering our people and setting common goals, we’re creating a path towards innovation, collaboration, and sustained success”.

Outside the office, Geoff tries to get back to nature as much as possible. You can find him hiking, camping, ATVing, or sometimes just relaxing with a good book.

As we celebrate this milestone with Geoff, we take this opportunity to express our heartfelt gratitude for his exceptional leadership over the past three years, including his dedication, and invaluable contributions to TMG. We can’t wait to see what’s in store as he continues his journey as Vice President of Operations.

MESSAGE FROM THE CEO

Celebrating Remarkable First Half of the Year

I am beyond proud of what we’ve been able to accomplish in the first six months between all of our divisions at TMG. Our commitment to unwavering quality and innovation has led us through some of our strongest quarters to date, backed by some exciting product launches and truly complex projects. None of this would have been possible without the shared efforts and resources between Tri-Mach, Industrial Contracting Solutions, and Advance Millwrights all working together towards a common mission.

I am beyond proud of what we’ve been able to accomplish in the first six months between all of our divisions at TMG. Our commitment to unwavering quality and innovation has led us through some of our strongest quarters to date, backed by some exciting product launches and truly complex projects. None of this would have been possible without the shared efforts and resources between Tri-Mach, Industrial Contracting Solutions, and Advance Millwrights all working together towards a common mission.

While I’m ecstatic about the growth we’re achieving by investing in Industry 4.0, new product development, and new complex integrated systems, TMG will never lose sight of our core values. People have always come first here, and we’ll continue to stay true to this by investing more and more into the enrichment of our communities, to our future tradespeople, and to our growing teams through training and development.

Looking to the future, we plan to continue this momentum in delivering comprehensive systems to better optimize the unique needs of our food, agriculture, and pharmaceutical industries. As population continues to grow throughout North America, producers will need new and creative solutions to keep up, and TMG will be right there alongside them as an expert advisor and tenured manufacturer of high-quality, sanitary, and robust equipment; aimed at helping our most critical industries do more, with less.

I extend a heartfelt thanks to our customers for their unwavering support, and to our employees for their tireless efforts. Together, we have achieved remarkable success, including being named one of Canada’s Best Managed for a third consecutive year, and together, we will continue to reach even higher heights.

Krystal Darling, B. Sc, MBA, ICD.D

Chief Executive Officer

Tri-Mach Groups Inc.